Page 1 of 2

Jointer jig for the tablesaw

Posted: Fri Jun 01, 2018 10:27 am

by JazzGuitarGimp

Hi All,

Making the rounds on YouTube, I stumbled across this nifty jig; which turns your tablesaw into a jointer. I imagine with a good-quality, 60-tooth blade, you could make glue-ready joints. I am going to make one with tall fences on both sides, so it's reversible, and have something like a 0.025" depth of cut on one side, and maybe 0.003" on the other side.

https://m.youtube.com/watch?v=21u4bou93 ... fullscreen

Cheers,

Lou

Re: Jointer jig for the tablesaw

Posted: Fri Jun 01, 2018 4:15 pm

by pompeiisneaks

Looks pretty cool, I've seen a few jigs of differing kinds for those purposes. I was turned onto a biscuit joiner here by xtian I think and/or some other forum members and LOVE it, I've tried manually doing finger jointing with a jig I built but it still was error prone, this, on the other hand, is ALMOST idiot proof. I say almost, because I've messed it up once or twice getting used to it, but now I'm pretty good at it.

~Phil

Re: Jointer jig for the tablesaw

Posted: Fri Jun 01, 2018 10:48 pm

by Geeze

Very cool! Thanks for posting it. The other cool feature is it's quieter than a jointer.

Russ

Re: Jointer jig for the tablesaw

Posted: Sun Jun 03, 2018 11:57 pm

by Phil_S

That's one approach. This is the other approach.

https://www.youtube.com/watch?v=ryaL6buKmyo

If you're gonna build a jig, you should know the options.

He also covers the edge jointing jig. I have 2 or 3 edge jointing jigs of different sizes, all built from scrap. Wedges work great to hold the work.

Re: Jointer jig for the tablesaw

Posted: Mon Jun 04, 2018 10:47 pm

by Winder

When I decided I wanted to build a cabinet for my Express, I watched a ton of YouTube videos ... from both of these guys, though Swan was the most active at the time. His approach gives you confidence that it's not necessarily rocket science. I'd never done a lick of woodworking, but bought a table saw, router table, router bits, saw blades, etc., and a 10.5 foot long by 10.5 inch wide, but 0.75-ish inch thick Cherry board (actually bought the board first ... then everything else). Worked off of Ron Worley's drawings (thanks Ron!!!). I built a crosscut sled, a beveling jig, and a router "gantry" jig to substitute for a planer and managed to build what I think is a pretty nice cab. Did this without a jointer. All I did was hold whatever piece I wanted to "joint" firmly on top of a piece of MDF that provided the straight edge against the saw fence and made a cut. Flip it around and cut the other side with the first cut against the fence and things are then parallel. Crosscut to size in the sled and you have a square piece of lumber (all of this after "planing" with the other jig).

Unless you're doing production work, or just lots of projects I guess, you can get on down the road with a few jigs. YouTube definitely helps, though common sense still applies! The glue up went just fine with the edges "jointed" with the table saw.

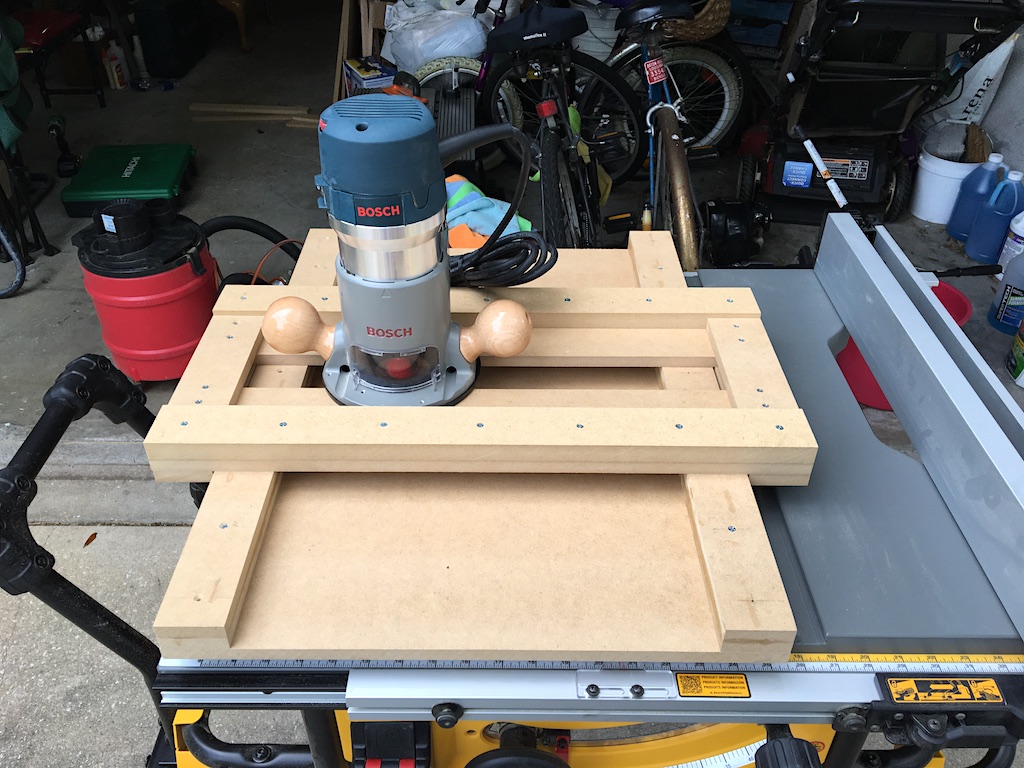

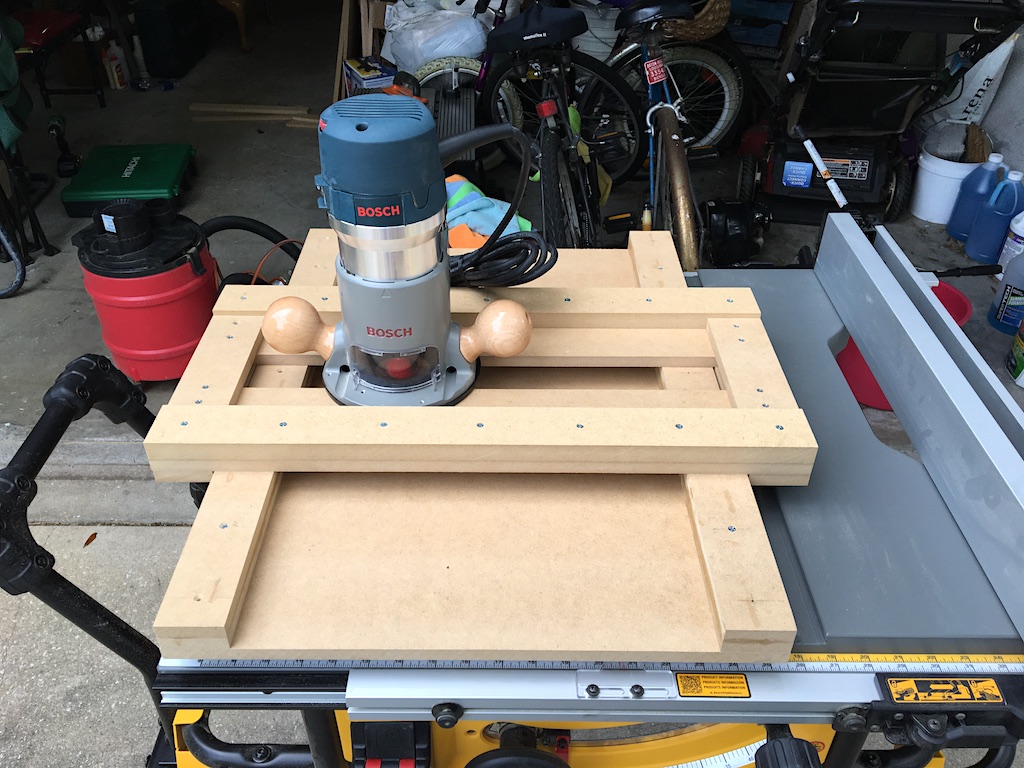

Here's the jig to use a router as a planer. There are obvious size limitations, but this was built to accommodate the material sized specific to the cab. Double sided tape is your friend, but if the board is two cupped/bowed to begin with, this jig might be a challenge to use.

One of the sides for the cab, now flat, and prior to "jointing" on the table saw.

Final results, no jointer or planer used (I think the hardest part is understanding how to finish the wood; I might approach it differently next time):

Took me quite awhile, practicing all cuts on scrap wood/MDF prior to making a "real" cut. Lots of pipe clamps (seemed most cost effective). Learned a lot (hey, finish sanding actually removes a ton of material! Dayum!).

Re: Jointer jig for the tablesaw

Posted: Tue Jun 05, 2018 2:55 am

by Phil_S

I built the router sled several times -- different sizes. One sagged in the middle under the weight of the router and I didn't notice until all the boards were thinner in the middle.

but I was working with scrap pine. I was still sorry because they were wide boards. The thing I found was that I needed a relatively thin bottom board to rest the router on or I couldn't set the bit for enough depth to reach the board. So, I built one on 1/4" fiberboard. I finally reinforced the fiberboard one that sags with L shaped aluminum. I haven't tried it yet, but I am hopeful it will work as it should.

The problem with trying to use the saw as a jointer is that boards can only be 6" wide. If you glue up 2, they won't be flat like you need them. For that you need a proper jointer (wide ones are pricey) or a router sled. The router sled can be set up to plane almost any size board. All you need to do is wedge the board between the rails of the bottom part with the sides. I've planed boards 4' long and 10'" wide and it works great (except with that last more compact one with the thin base

.)

I agree with Winder. Unless you need to mass produce, you can get by with a few inexpensive homemade jigs. I shop for scrap boards at The Loading Dock, a place that recycles building materials. I acquired a planer last year (Craig's List; have yet to break it out and use it) and got an 8' x 12" piece of white laminate MDF to cut up for a gizmo to kill the planer snipe for dirt cheap, maybe $2.

I don't have an inside dirty room where I can make sawdust. I have to wait for the warmer weather and work outside, which is fine. Unfortunately, the amount of rain we've been getting is ridiculous. Tomatoes are growing like there's no tomorrow, but I can't get outside to run the saw, planer, or router sled. Next weekend forecast is more rain. I don't know if I'll get any woodworking done this year.

Re: Jointer jig for the tablesaw

Posted: Tue Jun 05, 2018 8:53 pm

by Winder

Dust collection is an issue for sure. Routers and saws create a huge amount of sawdust. I keep the shopvac connected to the collection ports, bit it's inadequate really. Sag in the planing jig was a concern, so I used a combination of 3/4 and 1/2 inch MDF in such a way as to make if very sturdy. I've used my palm router with this too, but it's built for the big one.

The Wreck boards are about 9 inches wide. I can rip pretty wide with the saw I bought (24 inches, I believe), so I didn't have an issues "jointing" to 9 inches wide. Probably not the way to go in the long run, but worked fine for the cab. Lots of fun, though there's not a lot of suppliers of hardwood here locally. Repurposed wood is a good idea. I need to be on the lookout for those opportunities.

Re: Jointer jig for the tablesaw

Posted: Wed Jun 06, 2018 5:33 pm

by Phil_S

Winder, make yourself a dust extractor. Here's one example. There are many variations. This one is really simple and cheap. I've seen more elaborate, but what for?

https://www.youtube.com/watch?v=9w8jXS8Fjh8

Mine is a little more elaborate. It has an interior horizontal baffle to allow me to bring both hoses through the top where there were existing holes. The bucket was free from a construction site pile, and the plywood baffle was scrap. I had to buy the plastic pipe. The most expensive thing was the 4" hose from the extractor to the saw. The hose was $20 at Home Depot and I couldn't find anything cheaper. It works unbelievably well. Put a rock or a brick in the collector to keep it from falling over. I'm about to build a switch that will slave the vac to the saw. That will require a 20A circuit, which I have available.

The best reason for using an extractor is that your vac filter won't get clogged.

BTW, that cab came out very nice.

Re: Jointer jig for the tablesaw

Posted: Thu Jun 07, 2018 9:59 pm

by Winder

I like that. I probably have just about all of that stuff in my garage already. Thanks for posting the video!

Re: Jointer jig for the tablesaw

Posted: Wed Jun 13, 2018 10:03 pm

by cbass

Good idea for straight edging borads. I dont understand why he didnt just remove the riving knife and lower the blade. Then you you could make a smaller gap between the infeed and outfeed fence. Making it possible to edge shorter boards.

I think the router table jointer idea is better. It makes cleaner cuts than an actual jointer.

To me the biggest advantage of an actual jointer is flattening warped and cupped boards without a hassle.

Its pretty tough to straight line a warped board of it wont sit flat on your table.

Re: Jointer jig for the tablesaw

Posted: Thu Jun 14, 2018 11:03 pm

by Winder

cbass wrote: ↑Wed Jun 13, 2018 10:03 pm

Good idea for straight edging borads. I dont understand why he didnt just remove the riving knife and lower the blade. Then you you could make a smaller gap between the infeed and outfeed fence. Making it possible to edge shorter boards.

I think the router table jointer idea is better. It makes cleaner cuts than an actual jointer.

To me the biggest advantage of an actual jointer is flattening warped and cupped boards without a hassle.

Its pretty tough to straight line a warped board of it wont sit flat on your table.

I hear you. It's quite a lot of work "planing" the boards with the router jig. I was fortunate with the board I had that warp/twist/cupping was minimal. I was able to use double stick tape to hold them in place. I'd like to get more into woodworking, and a planer seems like a must for any significant amount of work. Very rewarding.

Re: Jointer jig for the tablesaw

Posted: Sat Jun 16, 2018 12:48 pm

by Geeze

Another option to the 'Making those unhappy planks behave' is a drum sander. A good dust collection system is a must with these. I have a 16" Jet that has milled miles of wood so far. I use 80 gr paper on the drum which leaves a decent surface to finish sand from. Not as fast as a planer but much much quieter and capable of milling to 1/16" stock.

There are options if you don't have tools -

Most of the specialty wood stores have a shop or are staffed with wood fanatics who have even better shops than can help with projects. I was all in a dither to buy a big ass band saw with a 1" blade for wide width resaw without the blade walk issue of smaller blades last year. Then sanity and reason came back [doesn't happen often - just ask my ex wife] when my wood store bought that exact model and told me they would charge $35 for a half hour of cutting time. No $2200 band saw for me - my 10" table top model does everything else.

Friends or neighbors. Last night I ran into an old carpentry buddy who just bought a monster band saw and he's 3 minutes away.

I joined a guitar builders guild and the members range from cigar box to $12000+ acoustics. The available tooling is just stupid - [besides the usual goodies] there are lasers, bed CNC routers all the way to a 4 axis HAAS VF4 machining center.

Russ

Re: Jointer jig for the tablesaw

Posted: Sat Jun 16, 2018 2:56 pm

by Phil_S

Russ makes an interesting point. I know of at least two co-op shops in Baltimore that give members access to a robust range of power tools. I haven't explored the options just yet. Not so convenient, limited hours, rules, etc. If you really need access to big equipment that you don't use all that often, paying by the hour is a great alternative. On the matter of the jointer, the more affordable ones are 6" or 8" wide and that's not really wide enough, IMO and you really don't need the small one for edge jointing. You can get a perfectly decent glue line rip on a table saw if you know how and have the right jig. YMMV.

Re: Jointer jig for the tablesaw

Posted: Sat Jun 16, 2018 9:19 pm

by cbass

did someone say drum sander? brb

Re: Jointer jig for the tablesaw

Posted: Sat Jun 16, 2018 9:57 pm

by cbass

beforr i gpt it set-up