faceplates from PCB

Moderators: pompeiisneaks, Colossal

faceplates from PCB

Thought I'd share this video I found that I followed to build a dumble style faceplate for a preamp I am building. after doing one faceplate I decided I wanted to do some various pcb's as well so I ended up doing a relay board, a 5v power supply board, a Fet board and a preamp power supply board as well. I sent my order to JLPCB and should be getting the boards by next week.

initial shipping cost is $20 from China but then it was $15 for 5 faceplates. The smaller fet boards were $2 for 5 boards

Anyways I think this is a very valuable video and hope someone finds it useful.

initial shipping cost is $20 from China but then it was $15 for 5 faceplates. The smaller fet boards were $2 for 5 boards

Anyways I think this is a very valuable video and hope someone finds it useful.

Re: faceplates from PCB

Unclear... are you saying JLPCB makes silkscreened faceplates?

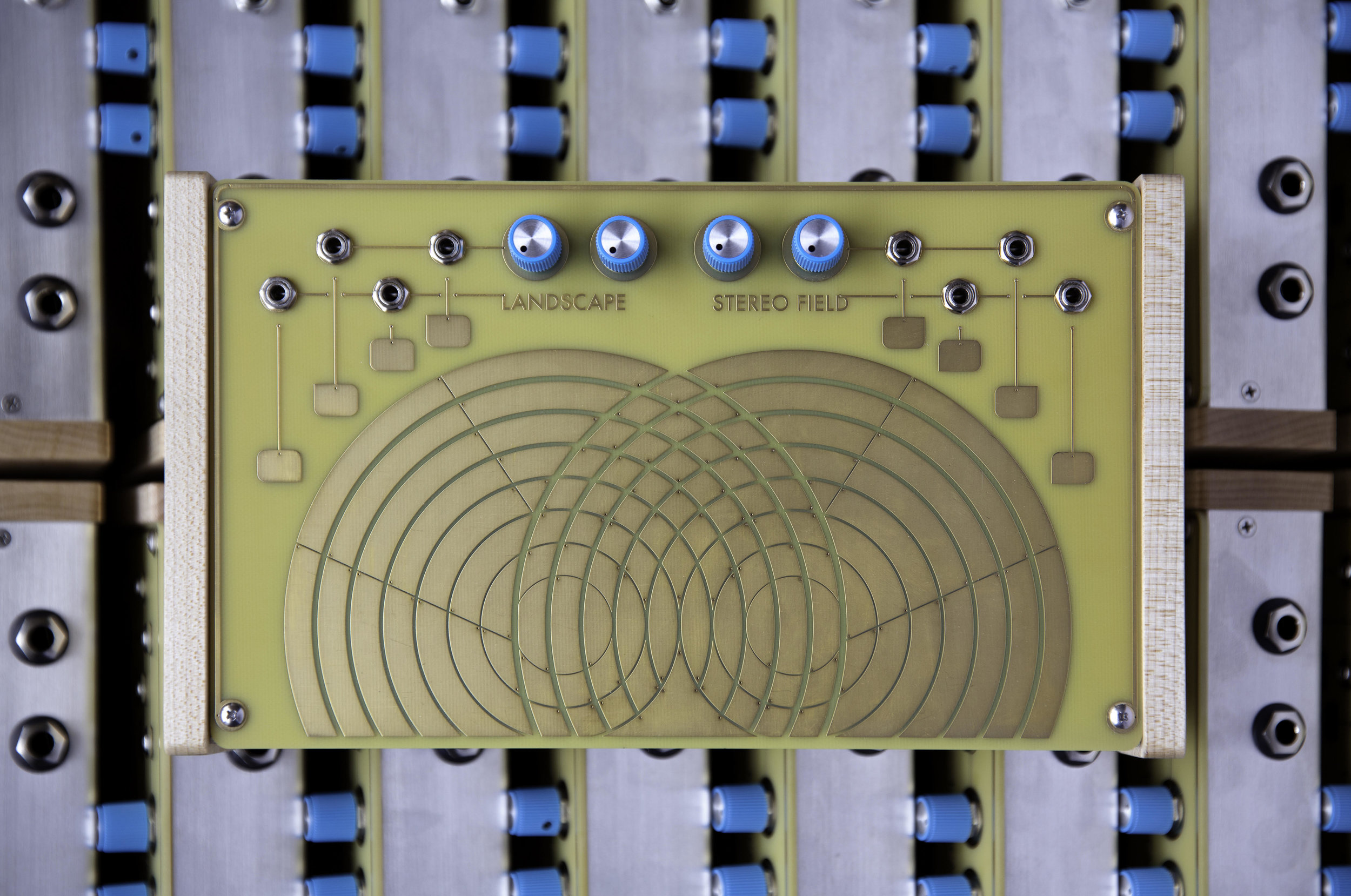

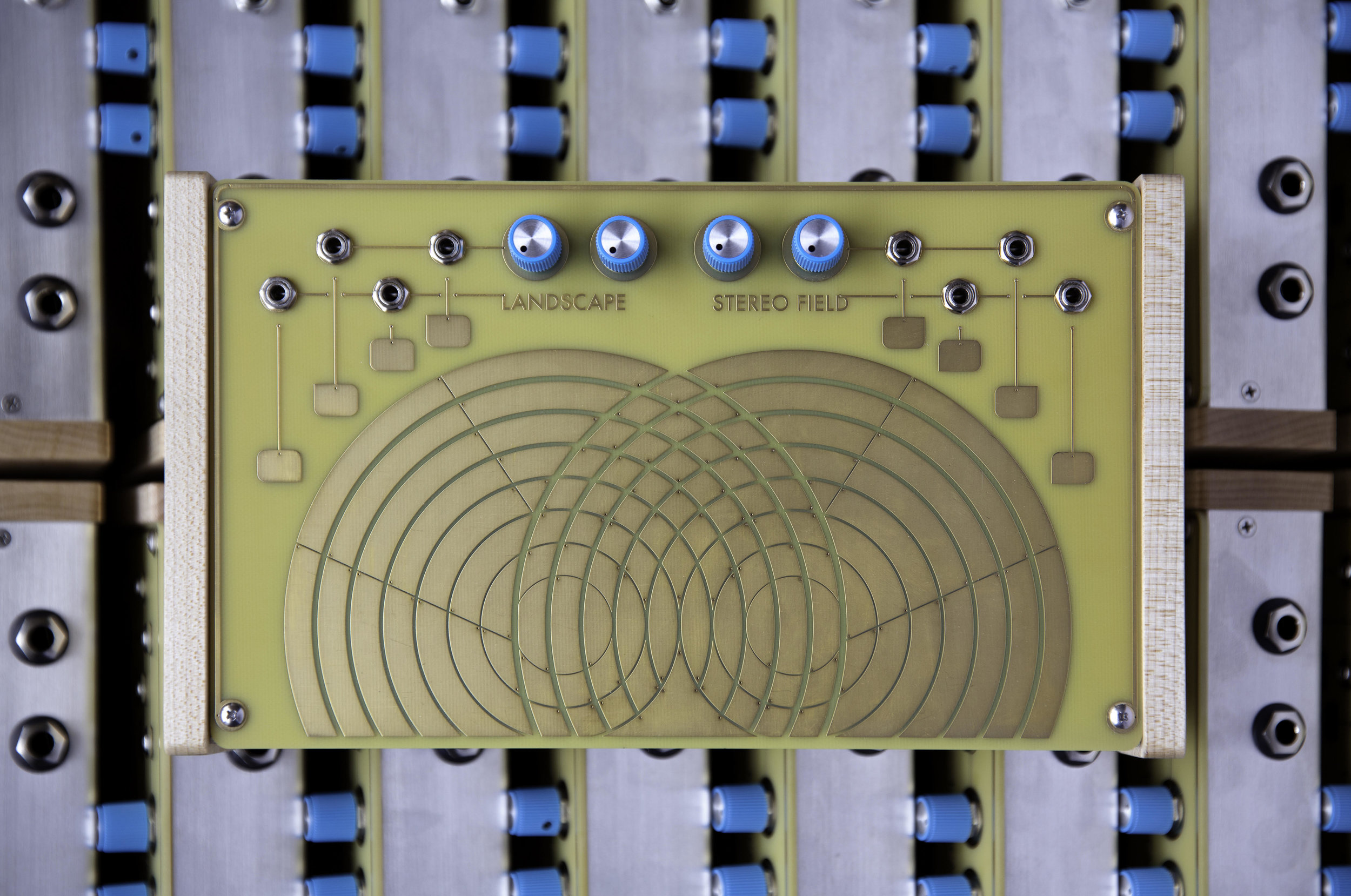

The topic of this post reminded me of these awesome looking effects electronics, where the PCB IS the faceplate:

https://www.landscape.fm

The topic of this post reminded me of these awesome looking effects electronics, where the PCB IS the faceplate:

https://www.landscape.fm

I build and repair tube amps. http://amps.monkeymatic.com

- pompeiisneaks

- Site Admin

- Posts: 4222

- Joined: Sat Jan 14, 2017 4:36 pm

- Location: Washington State, USA

- Contact:

Re: faceplates from PCB

He's saying what you just said, the guy made the faceplate from pcb material, he just used black solder mask over it.

~Phil

~Phil

tUber Nerd!

Re: faceplates from PCB

yep! looks killer too! The best part is i was meaning to learn kicad for a while and now after following this I only needed a little more research to figure out how footprints were assigned and a gallon of coffee later I was whipping through circuit boards.

they have black, red, white, green and blue solder mask so lots of options

they have black, red, white, green and blue solder mask so lots of options

Re: faceplates from PCB

Hello -

Common practice with the kool kids building & buying stuff over on MuffWiggler. A favourite new toy in my playroom is from MakeNoise, with their front panels all 100% gold-plate double-side PCB.

Encourage creativity but be careful with those plate voltages if you starting using it for more than decorative.

Best .. Ian

Common practice with the kool kids building & buying stuff over on MuffWiggler. A favourite new toy in my playroom is from MakeNoise, with their front panels all 100% gold-plate double-side PCB.

Encourage creativity but be careful with those plate voltages if you starting using it for more than decorative.

Best .. Ian

You do not have the required permissions to view the files attached to this post.

Re: faceplates from PCB

Oh cool! yeah no real circuit is on the faceplate for obvious reasons just 4 solser pads that can be used as screw holes to trick the pcb manufacturer into thinking its a complete circuit which they verify, but then I did a PS board to supply 3 B+ nodes with just my last name printed on the board but used .08" thick traces so hoping that will be adequate. I'll probably start a new thread here regarding good/safe practices as far as trace thickness and minimum distance between traces that could induce noise, etc.

had to google muffwiggler. I've messed around with some of the software synth that are eurorack style. Building some of those could be a fun little sidestep from tube amps!

had to google muffwiggler. I've messed around with some of the software synth that are eurorack style. Building some of those could be a fun little sidestep from tube amps!

Re: faceplates from PCB

Received the faceplates and a few other small boards I designed from JLPCB. Turned out better than expected.

You do not have the required permissions to view the files attached to this post.

Re: faceplates from PCB

That is so awsome! Nice work

Re: faceplates from PCB

Which thickness FR4 did you order? The .8mm I received from JLCPCB has a lot of oil/pressings on them so it's not a uniform look. I'm going to open a case with them about it but I'm curious about your observations.

You do not have the required permissions to view the files attached to this post.

Ryan

https://www.thetonegeek.com/

https://www.thetonegeek.com/

Re: faceplates from PCB

I've only ordered 1.6mm but its good to know they do .8mm as they were on the thick side. I started using IND COM for faceplates for better color options (brushed aluminum, multiple colors, etc) but still design PCB's often

On the faceplates I've ordered I've been lucky and they all turned out clean but have noticed some of the mask splattered on some of the PCB's I've done but it didnt bother me since they were going inside the enclosure. On a faceplate it would have been

On the JLPcb facebook group I follow I have seen others mention this problem but not sure what JLPCB has done to resolve it

I'd definitely bring it to their attention

Re: faceplates from PCB

Thanks so much! I just joined that group. Yeah once the faceplates are in the shell, you hardly notice the splatter since it's in the shadow anyway. The UV printing really makes the white stand out. The .8mm thickness is thick enough to not crack and it still allows me to sneak in a lock washer on the pots with a few threads for the nuts to twist down on. Thank you for sharing your experience!T Wilcox wrote: ↑Wed Feb 23, 2022 5:36 pmI've only ordered 1.6mm but its good to know they do .8mm as they were on the thick side. I started using IND COM for faceplates for better color options (brushed aluminum, multiple colors, etc) but still design PCB's often

On the faceplates I've ordered I've been lucky and they all turned out clean but have noticed some of the mask splattered on some of the PCB's I've done but it didnt bother me since they were going inside the enclosure. On a faceplate it would have been

On the JLPcb facebook group I follow I have seen others mention this problem but not sure what JLPCB has done to resolve it

I'd definitely bring it to their attention

Ryan

https://www.thetonegeek.com/

https://www.thetonegeek.com/

Re: faceplates from PCB

No problem, glad its been useful! That video covers a lot of useful info for our hobbies. I never considered doing pcb's until after following that vid then the only thing I really needed to figure out was how to find the correct footprints for components and it was just real easy.rccolgan wrote: ↑Wed Feb 23, 2022 2:10 pm

Thanks so much! I just joined that group. Yeah once the faceplates are in the shell, you hardly notice the splatter since it's in the shadow anyway. The UV printing really makes the white stand out. The .8mm thickness is thick enough to not crack and it still allows me to sneak in a lock washer on the pots with a few threads for the nuts to twist down on. Thank you for sharing your experience!

I checked out your tonegeek.com site and just happen to be starting on designing chassis using fusion 360 sheet metal program. I saw your SSS 004 chassis and they look real nice. Gonna try to do something similar for a high gain amp I've been working on designing, I may have some questions for you eventually once I'm getting closer to completing the design since you've been there and done that

Re: faceplates from PCB

nice, man! Feel free to import the SSS files to help speed things along. I also have a few YouTube videos how I used AutoDesk Inventor (lots of similar tooling and such as Fusion) https://www.youtube.com/watch?v=1NAkk2R5bLET Wilcox wrote: ↑Thu Feb 24, 2022 6:17 pmNo problem, glad its been useful! That video covers a lot of useful info for our hobbies. I never considered doing pcb's until after following that vid then the only thing I really needed to figure out was how to find the correct footprints for components and it was just real easy.rccolgan wrote: ↑Wed Feb 23, 2022 2:10 pm

Thanks so much! I just joined that group. Yeah once the faceplates are in the shell, you hardly notice the splatter since it's in the shadow anyway. The UV printing really makes the white stand out. The .8mm thickness is thick enough to not crack and it still allows me to sneak in a lock washer on the pots with a few threads for the nuts to twist down on. Thank you for sharing your experience!

I checked out your tonegeek.com site and just happen to be starting on designing chassis using fusion 360 sheet metal program. I saw your SSS 004 chassis and they look real nice. Gonna try to do something similar for a high gain amp I've been working on designing, I may have some questions for you eventually once I'm getting closer to completing the design since you've been there and done that

Ryan

https://www.thetonegeek.com/

https://www.thetonegeek.com/

Re: faceplates from PCB

Thanks man! I'm checking the video out now this will be very helpful!

Looks like autodesk inventor only offers 30day trial for personal use and I wouldnt use it enough to justify the cost unfortunately.

Ill see if I can get the SSS files into fusion 360 this weekend. If anything it would be very useful to copy some of the standard cutouts such as tube sockets, IEC, transformer cutouts,etc and use them rather than designing each from start

Thanks again!

Looks like autodesk inventor only offers 30day trial for personal use and I wouldnt use it enough to justify the cost unfortunately.

Ill see if I can get the SSS files into fusion 360 this weekend. If anything it would be very useful to copy some of the standard cutouts such as tube sockets, IEC, transformer cutouts,etc and use them rather than designing each from start

Thanks again!